I’ve been planning my 2021 garden since fall and have altered the plans several times. It’s important to keep a record of your plans, and I so far have 5 sketches for my 2021 garden dating back to September. This year will be my second year with a garden, and I’m planning for a 3 season garden. This means I have plans for all seasons, Spring, Summer, and Fall, and plans on what goes well together and what will go in once one stops producing. With this planning also comes many decisions. I have decided to start everything from seeds except what doesn’t use seed. I have also decided to use two new small raised beds and to use two more fabric pots than last year, however since I flipped the beds this fall, I only have one of the five bags I need filled. I’ll also be figuring out how to fill them early this spring. The soil is very compact here and not very fertile. We do have a compost bin, but it is much too small to be a hot pile, so though there is some dirt at the bottom, it will take a very very long time before I’ll get any significant compost from it.

The Plans

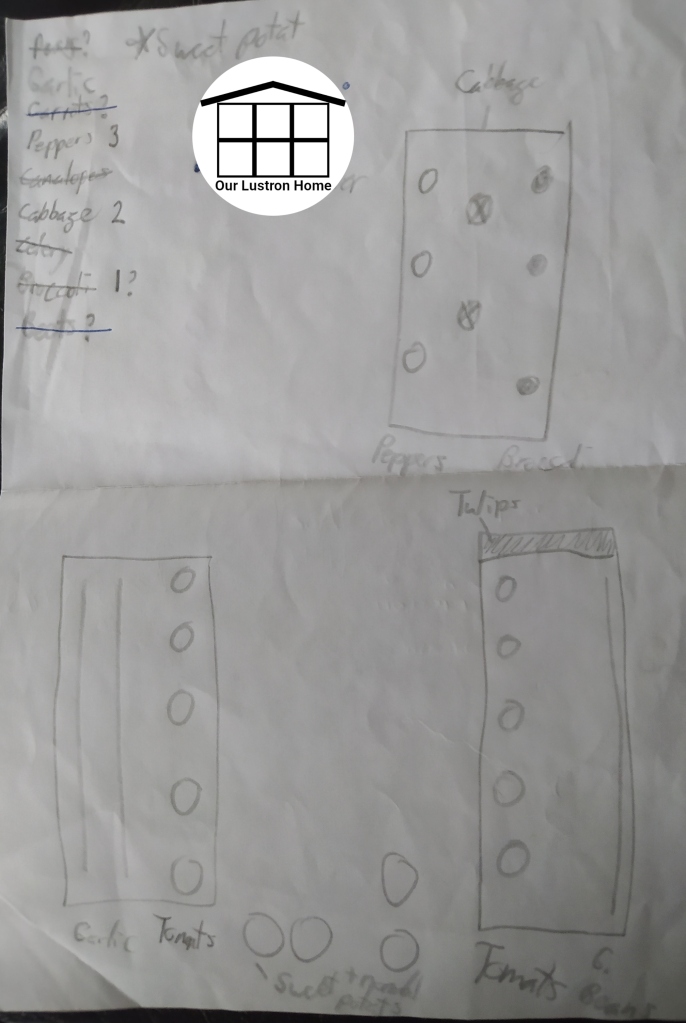

As I mentioned these plans have changed and evolved over time. The first things I did when planning my garden were to make a list of all the vegetables we eat a lot of and we feel would be a fun challenge for the next year. I also sketched out a layout for the garden. Then I began to place the plants I really wanted into the sketch accounting for plant spacing. Then, when you get to your last few plants you have to make the decision of what you want to plant this year. Take into account, how much you currently have stored, how often you eat it, and if you will have the means to store certain vegetables over an extended period of time.

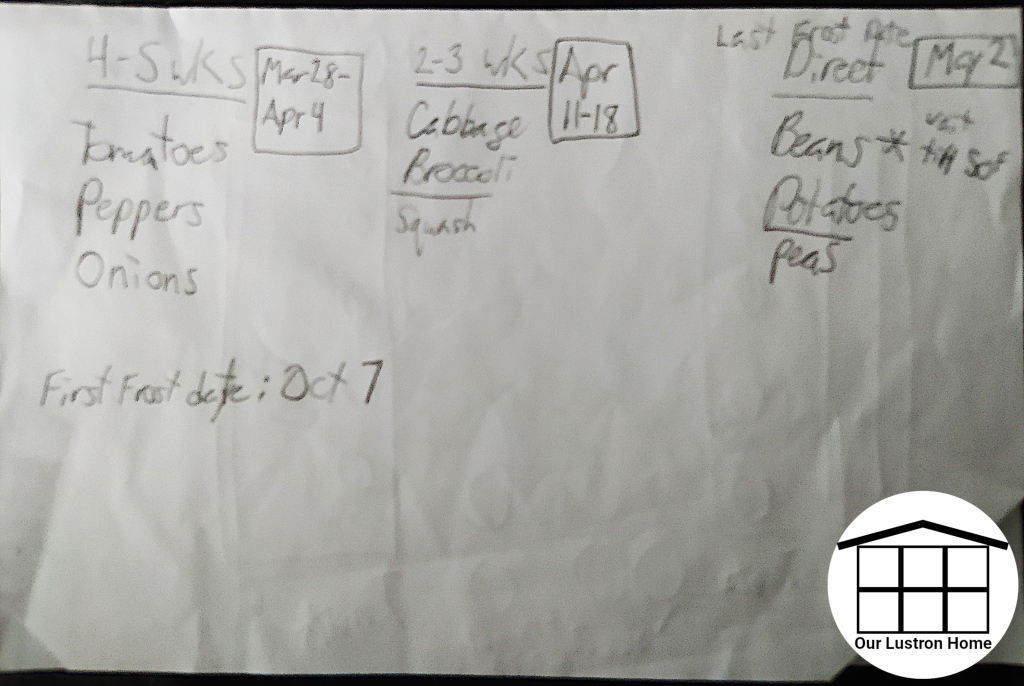

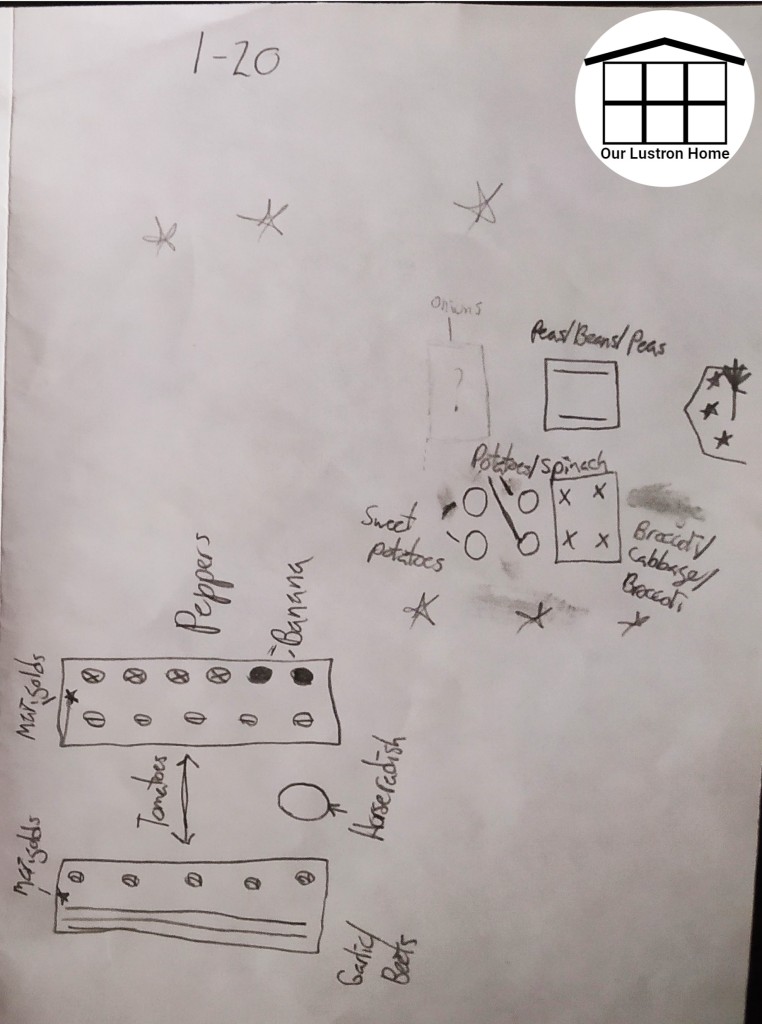

Once your vegetables are picked, you can tweak your plans over the span of a few weeks. However, when you finally are set on what you plan to grow, be sure to order seeds! Seeds are in a higher demand than normal and it could take a while to get seeds or for them to come back in stock. Beyond that, it will just be deciding when you can plant things, and what can be planted once one plant is ready to be pulled. For example, I already have my garlic in the ground and it came up before the hard freeze came, so I know that will be planted until late July when it will be time to harvest. After that, I will plant beets. I denoted that by a “/” on my sketch. I have several other plants I will be doing that with, I plant to plant Peas, once it gets warm, pull the peas and plant green beans, then come August/September, I’ll be able to plant a second planting of peas. I’ll be doing the same thing with my second new bed, but with two plantings of broccoli and one planting of cabbage. I also Plant to plant potatoes once the ground is warm, and once they are harvested, I will be planting Spinach in the fall. I am in zone 6A, so my timeline will likely be different than yours, however I hope you were able to get some helpful information.

Some possible questions you may have, I’ll try and answer before hand, but feel free to ask any questions you might have down in the comments. I’ll just hop into it. The circles not within a rectangle/square are my fabric pots. I plan to plant one with horseradish, two with sweet potatoes, and two with potatoes and spinach. The rectangles on the left side of the page are 4ft x 8ft beds that are 12 inches deep. These are the beds I started with last year. The square beds on the right of the page will be 4 ft x 4 ft beds, though they have not been constructed yet. There is also a possibility for another 4 ft x 8 ft bed for onions, but that will only happen if the cost of lumber comes down significantly before May. Most people in my area have a consensus not to plant anything in the ground before Memorial Day, however, plants like peas and broccoli are very cold hardy, so their spring planting will probably go into the ground beginning to mid-May. The picture above of dates and veggies underneath will be the days I will have to start my plants inside. For them, I will probably be starting them at the end of the time frame, just so they don’t get too big, if I do have to wait until mid- or late May before planting. What else… I will be planting two rows of tomatoes, and I’ll be doing one variety per row. I will also be planting both banana peppers and bell peppers in my pepper row. I have tons on Marigold seeds, so I’ll be starting them in every flower bed around my house, and I also learned to get them in the ground super early, or they won’t sprout. I learned the same with dill last year.

That’s all I can think to clarify. If you have any questions or comments, feel free to comment below! Thanks for reading!